Process optimisation & Conversions

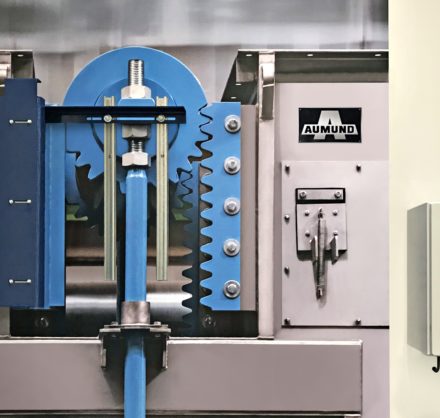

MECHANICAL ENGINEERING

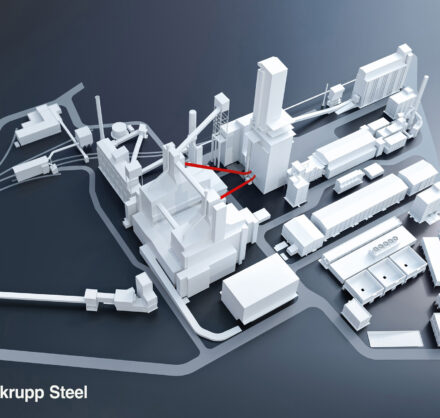

CONSULTATION & PLANNING

DESIGN & CONSTRUCTION OF MACHINERY

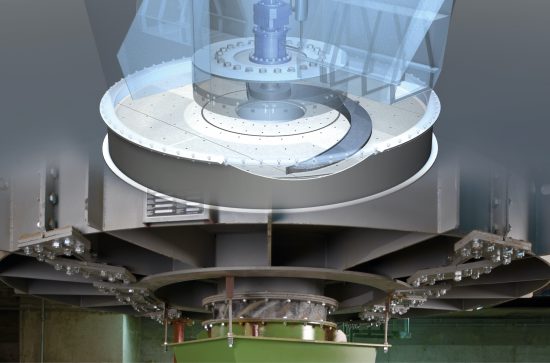

MAINTENANCE SOLUTIONS

PREMAS® INSPECTION

PREMAS® 4.0 PREDICTIVE MAINTENANCE SOLUTION