Cement

Specialised know-how in Conveying and Storage Technology for the Cement Industry all over the world

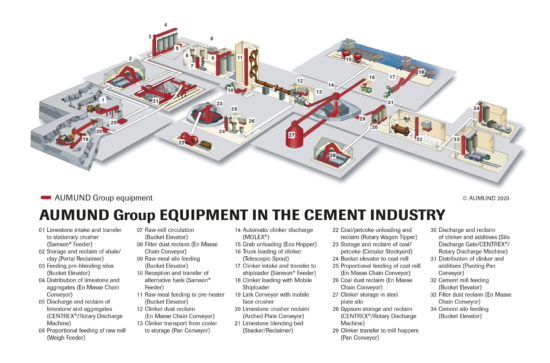

The AUMUND Group, with its manufacturing companies AUMUND Fördertechnik GmbH, SCHADE Lagertechnik GmbH and SAMSON Materials Handling Ltd, is a leading international specialist in conveying and storage technology, in particular for hot and abrasive bulk materials. From the quarry or port to material preparation, in the production process and on to loading of the finished product, tailor-made equipment is designed, manufactured, installed and commissioned all over the world.

The logistics of the various raw materials, combustibles and additives is an important aspect in the production of cement. Limestone and other raw materials have to be kept in stock in sufficient quantities to ensure continuous production even if there is an interruption in supply.

With a wide range of products AUMUND provides optimised solutions for feeding material to the crusher and extracting it after crushing, as well as conveying it on to the raw materials storage:

- Material reception and crusher feeding

- Hopper and crusher discharge

Raw Materials Preparation

For silo and bin feeding, and discharge of raw materials and additives from hoppers, AUMUND Fördertechnik offers a range of discharge systems, adapted to the specific material characteristics of the different bulk materials:

- Conveyors for feeding and discharge of silos and hoppers

- Feeding of the raw material mill and further process steps

- Feeding of the raw meal silo

Kiln Feeding – Raw Meal Conveying to the Heat Exchanger

AUMUND supplies Belt Bucket Elevators which can be designed for high-capacity kilns. Daily production capacities of 12,000 Tonnes or more have become standard.

Combustibles – Reception, Storage and Conveying

The AUMUND range of products includes various machines for feeding and recirculation of the coal mill (for coal as well as for alternative fuels).

Reception of Alternative Fuels

AUMUND Fördertechnik offers products for the reception of alternative fuels such as tyre chips, plastics, sludge, biomass and many others.

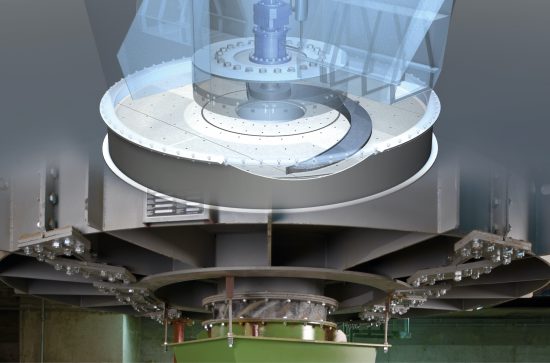

Sometimes the alternative fuels have to be dried and ground. AUMUND Fördertechnik now offers the new and patented AU-Mill® for this purpose.

AUMUND Pan Conveyors operate successfully all over the world in mill pre-hopper feeding. Clinker and additives such as gypsum or sludge can also be transported with this equipment. For reception of additives the versatile Material Feeder type Samson® is the ideal solution.

Hopper Discharge

The choice of machine for hopper discharge depends on the specific characteristics of the bulk material. Depending on the material and the location, a range of Pan Conveyors and Discharge Arm Systems are offered.

Other applications:

- Collecting Conveyor at the cement mill

- Feeding and recirculation at the cement mill

- Filter dust extraction

Detailed concept and careful design of the clinker storage and conveying system contribute considerably to the cost-effectiveness of the complete plant. AUMUND Fördertechnik can draw on over 60 years of technological expertise and international experience backed up by thousands of reference installations.

The type of storage depends on the site situation and the required storage capacity. There are various design possibilities, and the best solution will become apparent as a result of the plant planning process.

Clinker Loading and Dispatch

AUMUND offers a range of machines for loading bulk cement and clinker onto trucks, trains or ships. Efficient dust suppression, integrated dedusting and optimised automated operation are available at capacities between 100 and 750 tph, in some cases even up to 900 tph.

Clinker Storage Systems

In the cement industry more than 20,000 AUMUND Group references are being applied worldwide. Design, implementation and also modernisation of clinker storage installations, customised as per requirement, achieve maximum customer benefit.

- Adapted to the customer´s specific requirements, all transport processes are constantly optimised based on innovations and the latest technical know-how.

- Combining economic and ecological aspects including future demands

To receive an optimum overall conveying and storage layout, early involvement of AUMUND´s experienced engineers is recommended.

PRODUCTS & SYSTEMS

Flowsheet

Discharge Systems

Bucket Elevators

Chain Conveyors

Apron Feeders

SAMSON® Material Feeder (fixed)

Samson® Material Feeders (mobile)

Pan Conveyors

Telescopic Spouts

Circular Storage

Longitudinal Storage

Stackers, Reclaimers & Combined Machines

Wagon Unloading Systems & Wagon Tipplers

Eco Hoppers

Shiploader